|

Hangzhou Modern Color Printing Co., Ltd.

|

Gold Index: 48205

Product (528)

- photo book printing (15)

- children's book printing (29)

- Paper crafts printing (13)

- hardcover book printing (42)

-

softcover book printing

(116)

- sewn binding book (91)

- perfect binding book (25)

- PVC cover book (5)

- cloth cover book (18)

- flexi cover book (19)

- silk cover book (5)

- leather cover book (7)

- coil-bound book (11)

- thread-bound book (16)

- embossed cover book (9)

- saddle stitched book (30)

- greeting card printing (39)

- Apparel catalogue printing (7)

- backless bound book (7)

- business brochure printing (29)

- clothing magazine printing (23)

-

packaging box printing

(35)

- cosmetic packaging box (14)

- gift box printing (21)

- Paper calendar printing (13)

- writing notebook printing (17)

- gift paper bag (23)

Process Flow (1)

Equipment (9)

Quality Control (2)

Customer Evaluation (7)

Offices&workshops (7)

Team work (1)

News (10)

Certificates (5)

Credit Report

Products Index

News

Introduction of gravure (raised) printing technology

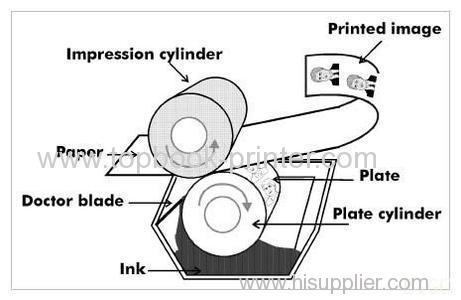

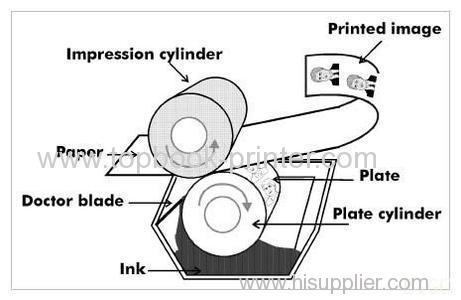

The distinctive feature of gravure printing technology is the fact that the image elements are engraved into the surface of the cylinder. The non-image areas are at a constant, original level. Prior to printing, the entire printing plate (non-printing and printing elements) is inked and flooded with ink. Ink is removed from the non-image (by a wiper or blade) before printing, so that ink remains only in the cells.

The ink is transferred from the cells to the printing substrate by a high printing pressure and the adhesive forces between printing substrate and ink. It should be noted here that only variable-depth gravure printing and more particularly variable-area/variable-depth gravure are of any significance, due to their high quality. Pure variable-area (halftone) gravure is scarcely used nowadays.

Traditional, that is to say only variable-depth, gravure printing is also increasingly losing its importance since the printing plate production is based on complicated copying and etching processes that are almost impossible to standardize.

It is for this reason that variable-area/variable-depth gravure printing processes, which in industry are based on electronic/mechanical engraving (using a stylus) of the gravure cylinder, are becoming prevalent.

Pre Page:

Top best 10 printing companies all over...

Next Page:

The tourism