|

Hangzhou Modern Color Printing Co., Ltd.

|

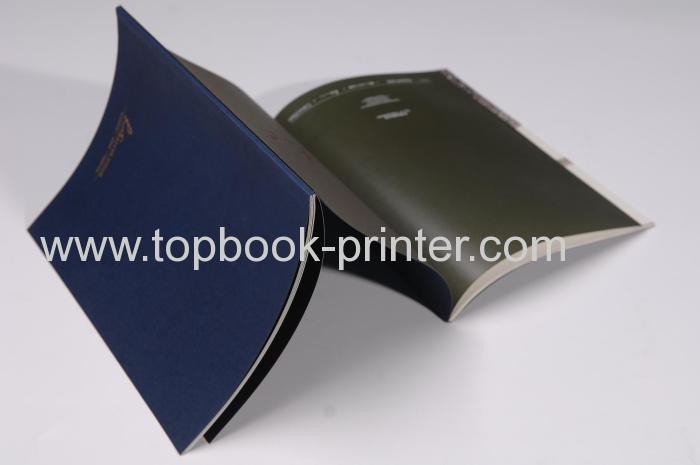

Hot-stamped conjoined sewn linen cover paperback book

| Price: | 0.5~2.0 USD |

| Payment Terms: | T/T,L/C,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

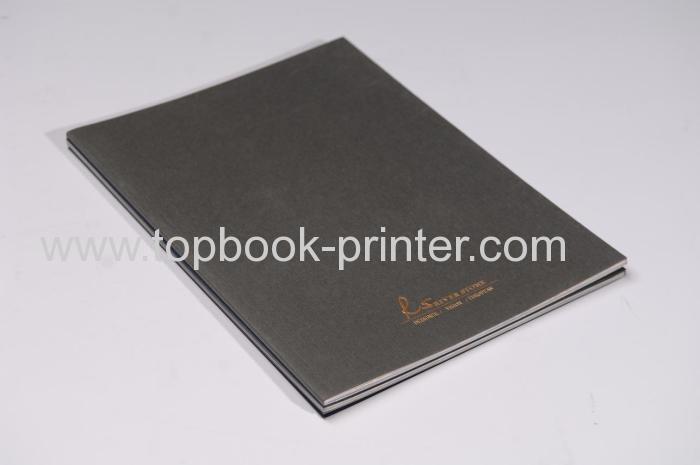

1. Style: conjoined structure;

2. Cover: embossed cover;

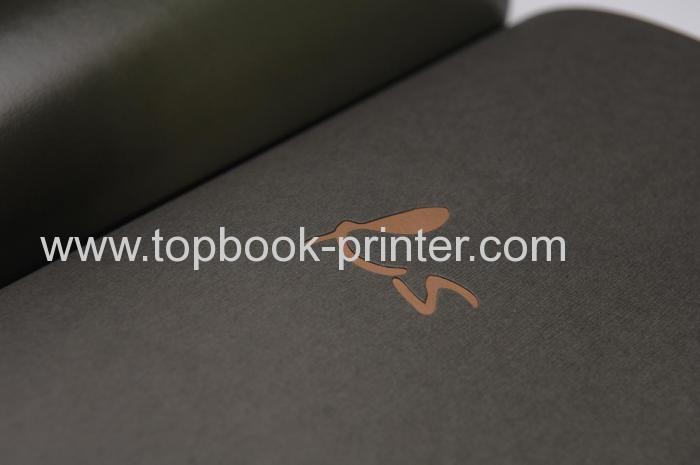

3. Surface finishing: hot stamping or foil stamping;

4. Binding: sewn glue binding

Top-grade hot-stamped conjoined sewn embossed cover paperback book printing. Reliable hot-stamping conjoined sewn embossed cover paperback book printer. We are a top hot-stamped conjoined sewn embossed cover paperback book printing expert or specialist.

Conjoined book is a siamesed book designed for meeting the special demands of customers. It's usually made by binding two or three books by hands, of which two books share the same cover. The number of its covers is more than two, and they should be made of the same cover material. The binding direction of books is different from each other for conveniences of book binding.

We can also design different shapes of conjoined books, such as the book with smaller covers (the size of cover is smaller than that of inside page). All kinds of special-shape cover books can be printed as per the customers' requests.

Number of spines | Two or three |

| Cover | Embossed paper+gloss/matt art paper |

| Finishing | Gold stamping and die cutting |

| Inside pages | FSC-certified art paper |

| Binding | Sewn binding |

Cover:

Hot stamping:

Conjoined structure:

Die cutting:

Inside pages:

Production process:

Packing: packed in poly bags and international standard cartons, and placed on European or American standard pallets

International standard pallets with fumigation certificates

Visit of foreign customer:

FAQ:

1. What is perfect binding?

In perfect binding (also known as softcover binding), pages are folded, gathered, sewn, and glued into a cover to form a squared-off spine. Perfect binding is the preferred binding method for graphic novels, trade paperbacks, softcover children's books, catalogs, literary journals, and quarterly magazines.

2. How is it made?

In traditional perfect binding, sheets are printed, folded, and assembled into their proper page order. From there, the side of the book block is cut off, and the pages are glued into a cover to form a squared-off spine.

However, this methodology leads to perfect bound books that don't open flat, and with pages that can fall out over time.

We use a more sophisticated method, where instead of cutting the book block, the pages are smyth sewn together before being glued into the cover. This methodology provides a far more durable finished product, since the pages are both sewn and glued, and the books can open much flatter, so much less content is lost in the gutter between pages.

3. What are its design considerations?

It's important to note that because the book block is glued into the cover, perfect bound books have 10 millimeters of area on their inside covers that will be glued to the first (and last) inside page.

This means that all artwork on the inside covers, as well as the first and last inside page, should be kept at least 10mm away from the spine.

Cover Design: Because perfect bound projects have a spine width that varies based on number of pages and paper weight, every perfect bound cover has different size requirements. You can use our perfect binding cover layout guide to design your cover.

4. How long does their production time need?

After being sent to press, perfect bound projects take 7-10 days to manufacture, after which they are shipped out to you via your chosen shipping method. The final delivery time is determined by your proofing and shipping options