|

Hangzhou Modern Color Printing Co., Ltd.

|

spiral plastic coil UV coating cover coffee hardcover or hardback book

| Price: | 0.5~2.0 USD |

| Payment Terms: | T/T,L/C,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1. Printing: double-side offset printing;

2. Case: embossed paper+greyboard;

3. Surface finishing: UV coating;

4. Binding: wire and spiral binding.

Top-quality spiral plastic coil UV coating cover coffee hardcover or hardback book printer. All types of spiral plastic coil UV coating cover coffee hardcover or hardback book printing solutions can be supplied as per your requests. We are a top spiral plastic coil UV coating cover coffee hardcover or hardback book printing expert or specialist.

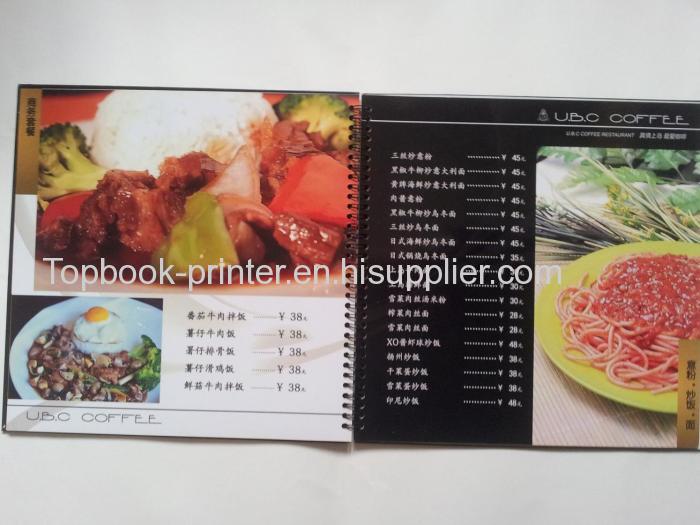

Spiral binding coffee book is a hardcover book preferred by most of coffee hall owners. A coffee table book is an oversized, usually hard-covered book whose place is for display on a table intended for use in an area in which one would entertain guests and from which it can act to inspire conversation. Such coffee book often introduces the names of dishes and beverages, including their features or favors.

Coil binding, which can be also known as spiral binding, is a common book binding mode for creating books, brochures, catalogues and notepads, etc. This binding mode is called as spiral coil, color coil, colorcoil, ez-coil, plastic coil, spiral binding, plastikoil and coilbind. Books bound with helical coil (spiral coil) can open flat on a desk or table and easy for 360 degree rotation. This binding mode is durable and is often used for books that need to be posted. Spiral coil binding spines are also available in several colors and sizes.

| Printing | four color offset printing |

| Case | embossed paper+greyboard |

| Finishing | spot UV coating |

| Binding | Spiral binding |

Cover:

Spiral plastic coil:

Spot UV coating:

Inside pages:

FAQ:

1. What are Wire and Spiral binding?

In wire and spiral binding, holes are drilled along one side of the printed pages, and then either a wire comb is clamped down into the holes, or a plastic spiral is threaded through them. Wire and Spiral binding both lay very flat and are often used for cookbooks and manuals.

2. How are such books made?

To create a wire or spiral bound book, parent sheets are first printed, cut and assembled (but not folded, unlike other binding methods). Holes are then drilled into the binding edge of the document. For wire binding, these holes are straight up and down, and for spiral binding they are drilled at a precise angle that depends upon the size and thickness of the book and the plastic spiral used. From there, either wire comb is threaded and clamped down by hand (for wire binding) or spiral is threaded through the holes by hand (spiral binding) to create the final product.

3. What are their design considerations?

The most important thing to remember when designing a wire or spiral bound project is that holes will be drilled 10 millimeters inside the trim line on the bound side of the document. Because of this, we recommend keeping all important content at least 10mm inside of the trim line on the side that will be bound, since any content inside those 10 millimeters may be obscured by the holes drilled or by the binding itself.

Another thing to consider with wire and spiral bound projects is that unlike most other binding methods, your page counts do not have to go in increments of 4. Instead, they can be in increments of 2 (both sides of a sheet of paper), since wire and spiral books do not have to be folded in the binding process.

Finally, wire and spiral pages can have finishes (which are usually reserved for covers) throughout their inside pages. Many manuals designed for outdoor use or cookbooks designed to be spill-resistant will use a lamination on every page.

4. How long does their production time need?

After being sent to press, wire and spiral bound projects take two weeks to manufacture, after which they are shipped out to you via your chosen shipping method. The final delivery time is determined by your proofing and shipping options