|

Hangzhou Modern Color Printing Co., Ltd.

|

Cloth finished paper cover casebound book

| Price: | 1.42 USD |

| Payment Terms: | T/T,L/C,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

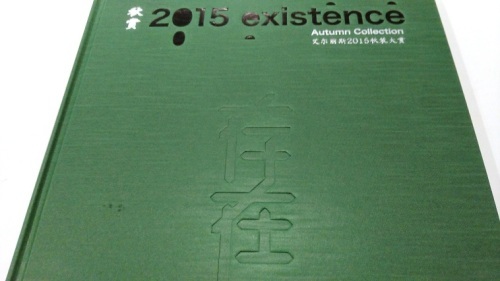

1. Surface finishing: blind emboss and foil stamping;

2. Material of cover: Cloth paper;

3. Greyboard: 2mm greyboard;

4. Binding: case binding.

The cover surface finishes of this cloth texture paper hardcover book incldude blind embossed letter press, black gold stamped text and silver stamped logo.

Cloth Texture Cover Sales Hardcover Brochure Specifications:

Final Size: 8"in W x 10.5"in H

Inside Pages: 44 (includes cover)

Inside Pages INK: 4/4 - CMYK / CMYK

Inside Paper Stock: 200gsm, Art paper, Matte White

Bleed: Full Bleed .25"

Finish: Blind Letter Press and Foil Stamping

Packaging: Placed in shipping carton and covered so all books do not get dirty

| Cover | Cloth texture paper+greyboard |

| Finishing | Silver stamping & blind emboss |

| Inside pages | Matt coated art paper |

| Binding | Case binding |

Cover of cloth texture cover hardback book:

Inside pages of cloth texture cover hardback book:

Blind emboss and hot stamping:

Spine of cloth texture cover hardback book:

Production process:

Hardcover/Casebound Cover Artwork Setup Guide

Because we take a single printed sheet and wrap it around 3 pieces of sturdy greyboard to create the hardcover case for your book, your artwork should be created as a single spread.

The "Page Height" and "Page Width" measurements in the guide below should be the same as the inside pages of your book.

Next, you'll have to accommodate for your book's spine.

You'll also have to account for the area marked 'foldover,' which is printed, folded over, and glued to the inside of the greyboard case to hold everything together as you can see in our page on casebinding. Most of this area is not visible in the final book.

In addition, designs for hardcovers need to take hinge into account, which is the area next to the spine that has no greyboard underneath. For more information, see www.printninja.com/hinge

Finally, keep in mind that hardcover cases, like all offset printing, exhibit minute variance in their production. This means that you should be careful to keep important text and graphics away from the edges between sections, since printed elements will often shift a millimeter or two in final production.